Palm Kernel Shells and Coconut Shells have both a high level of pure carbon. About 45% of Palm Kernel Shells and 40% of Coconut Shells is pure carbon. You can see it visually when cracking the shells that they are black inside. The black material is pure carbon.

Pure Carbon has a number of applications. The most valuables are as base material for activated carbon and carbon fibers. Activated carbon is being used for purification in numerous applications. Carbon fibers is being used as a very strong and lightweight material in numerous high-tech products.

Simple made charcoal is not good enough for either activated carbon nor carbon fibers. In both cases the carbonisation will be the first step, but the carbonisation must reveal clean and pure carbon without any ash, any uncarbonised material and any contaminants.

Palm Kernel Shell Charcoal. The carbon content is more than 80%.

Activated Carbon is a form of carbon processed to have small, low-volume pores that increase the surface area available for adsorption or chemical reactions. Activated is sometimes substituted with "active". Activated carbon is usually derived from charcoal. When derived from coal[1][2] it is referred to as activated coal. Activated coke is derived from coke.

Due to its high degree of microporosity, one gram of activated carbon has a surface area in excess of 3,000 m2 (32,000 sq ft) as determined by gas adsorption. An activation level sufficient for useful application may be obtained solely from high surface area. Further chemical treatment often enhances adsorption properties.

Activated carbon is used in methane and hydrogen storage, air purification, solvent recovery, decaffeination, gold purification, metal extraction, water purification, medicine, sewage treatment, air filters in gas masks and respirators, filters in compressed air, teeth whitening, production of hydrogen chloride in dark and many other applications.

Activated Carbon made from Coconut Shells is recoqnised as the finest kind of activated carbon especially suitable for removing aromas from organic materials and therefore widely used in the food processing industry.

Activated carbon is carbon produced from carbonaceous source materials such as bamboo, coconut husk, willow peat, wood, coir, lignite, coal, and petroleum pitch. It can be produced by one of the following processes:

Activated Carbon Pellets. Semi crunched activated carbon.

Activated Carbon Powder. Fine granulated activated carbon.

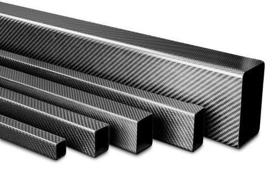

Carbon Fibers (alternatively CF, graphite fiber or graphite fibre) are fibers about 5–10 micrometres in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion.

These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers but has superior quality.

To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber as the crystal alignment gives the fiber high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric.

Carbon fibers are usually combined with other materials to form a composite. When impregnated with a plastic resin and baked it forms carbon-fiber-reinforced polymer (often referred to as carbon fiber) which has a very high strength-to-weight ratio, and is extremely rigid although somewhat brittle. Carbon fibers are also composited with other materials, such as graphite, to form reinforced carbon-carbon composites, which have a very high heat tolerance.

In 2012, estimated global demand for carbon fiber market was $1.7 billion with estimated annual growth of 10–12% from 2012–2018. The strongest demand for carbon fiber come from aircraft and aerospace, wind energy, as well as the automotive industry with optimized resin systems.

Carbon tubes as extremely strong and extremely lightweight construction material.

F1 racing car with a structure made of carbon fiber